Before our products get to adorn the hoods, fenders, tyres, or tailgates of renowned brand cars like Audi, BMW, Daimler, or VW, technical precision is to be applied. This is what it takes to ensure the end product meets our customers’ high expectations towards quality and appearance. That’s the reason why we leave nothing to chance and assume the entire production and assembly process. In this course, we make use of most various production techniques.

The future is built today.

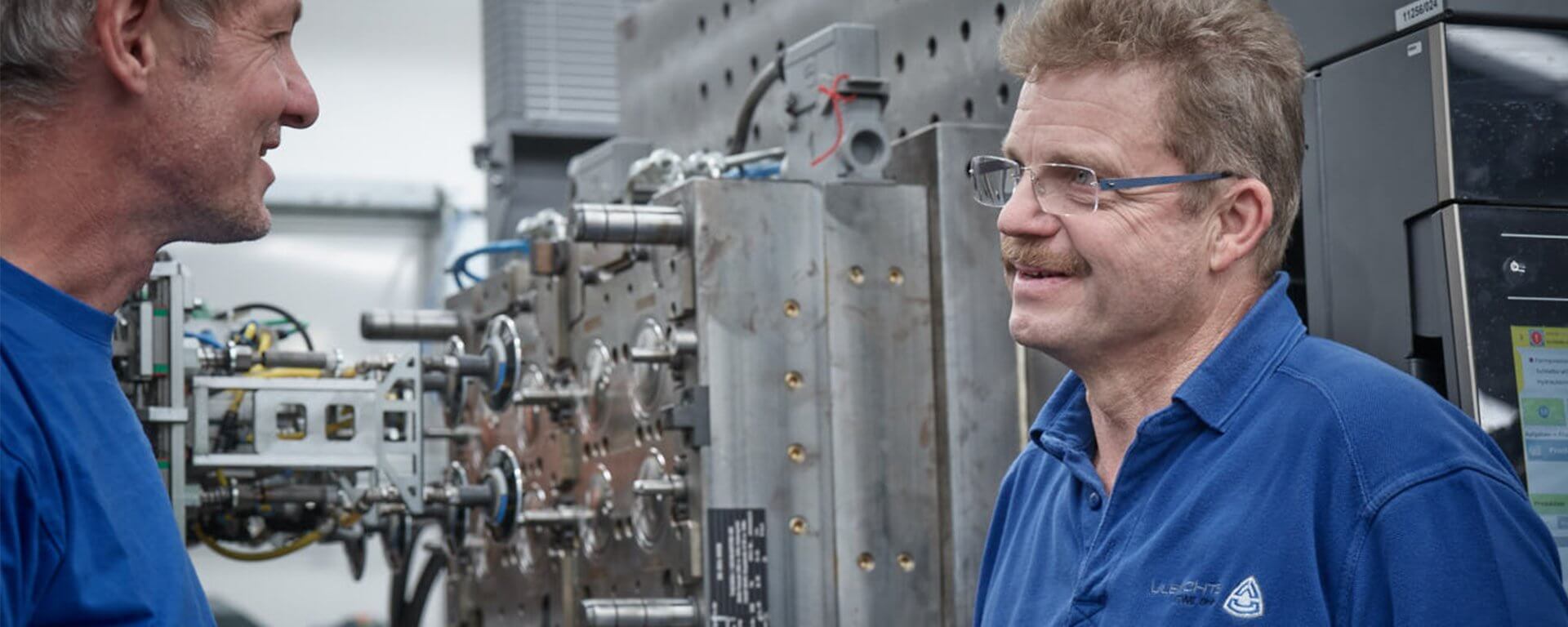

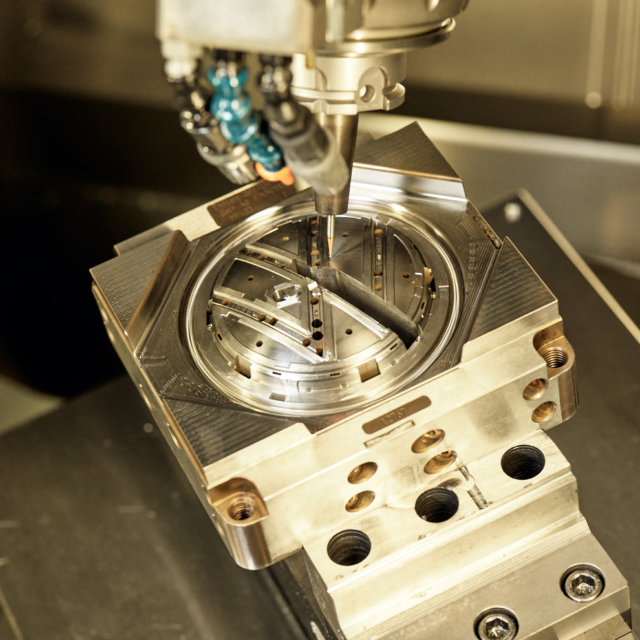

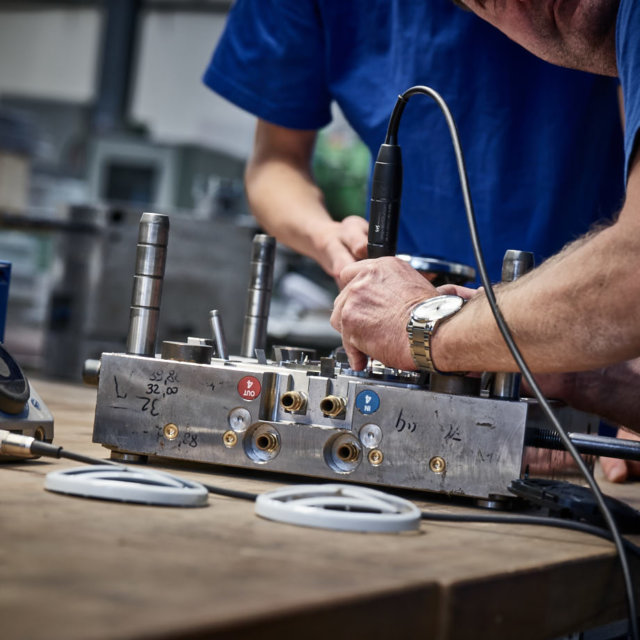

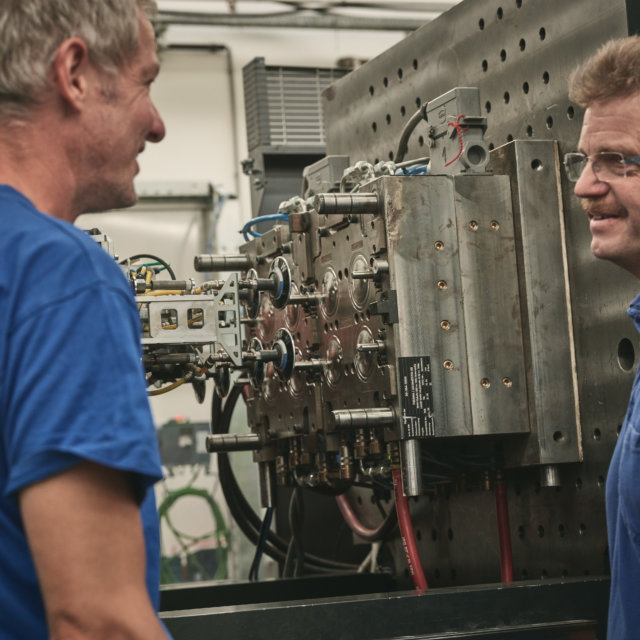

Tool making

Our injection moulding machines can handle most various plastics; our automatic assembly machines handle most various individual components. ULBRICHTS Automotive – that is our engineers’ and designers’ inventive spirit combined with our toolmakers’ skills and longstanding experience. The advantages of proprietary tool making are obvious: we realize ideas and solutions rapidly.

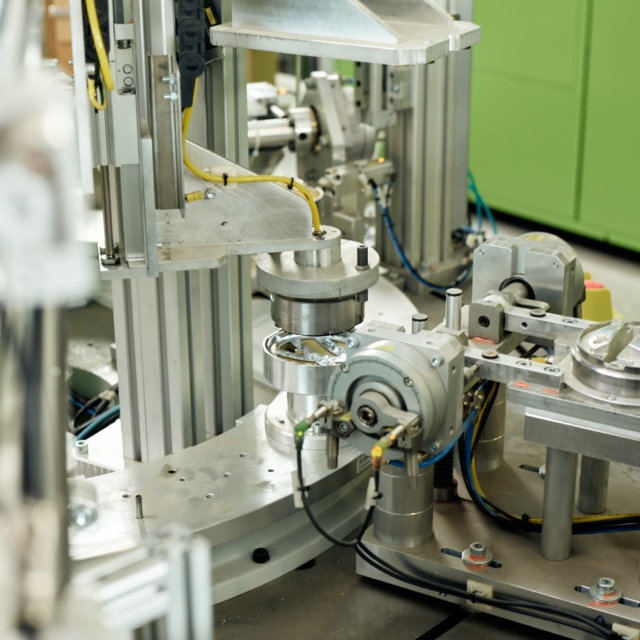

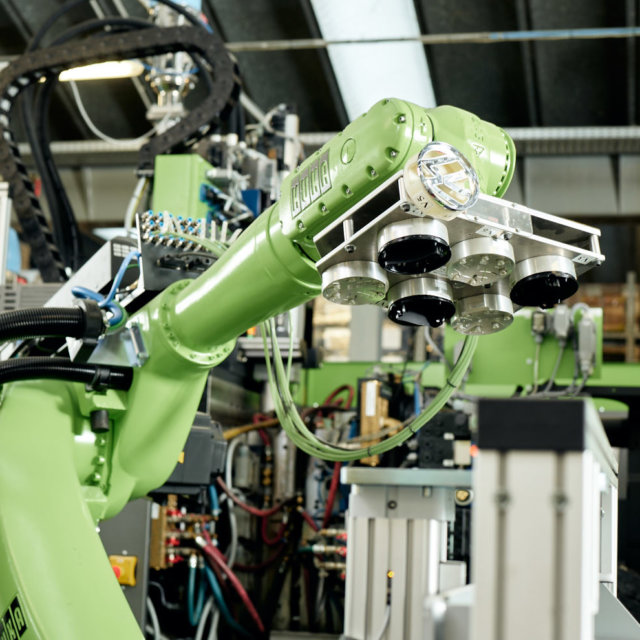

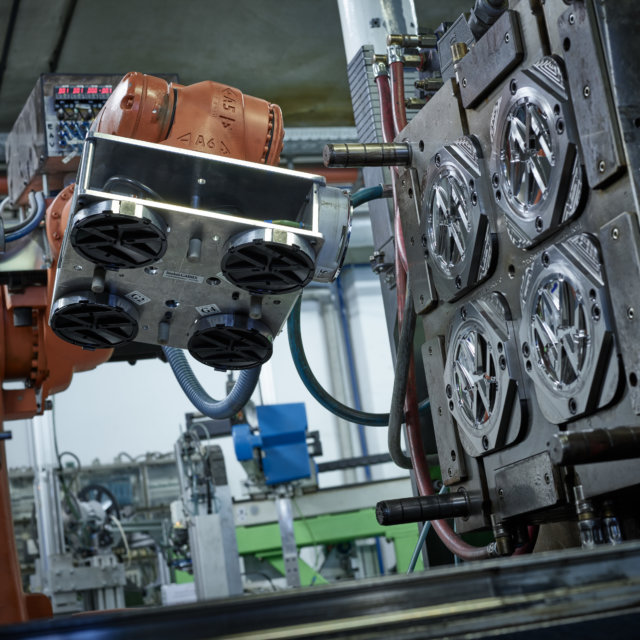

Device construction / Automation technology

Fully-automatic manufacturing platforms don’t come from nothing. They are based on the engineering expertise of our proprietary mechanical engineering department. In cooperation with long-established partners, we design machines and automation processes that facilitate exactly what our customers expect from us: customised solutions and products of perfect quality. The options with respect to the components’ design and functionality are nearly unlimited. Our experts make sure that production, assembly, quality control, and packaging are implemented at a high automatic level.

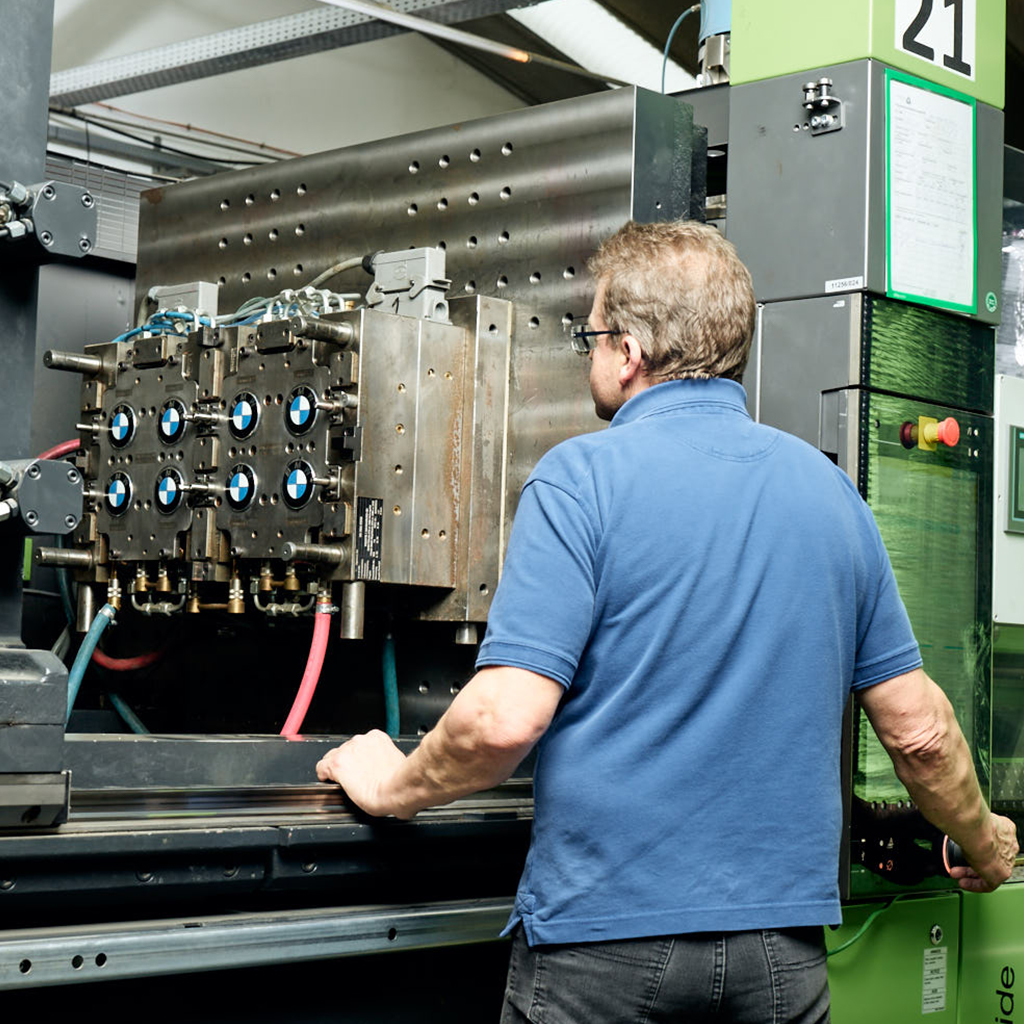

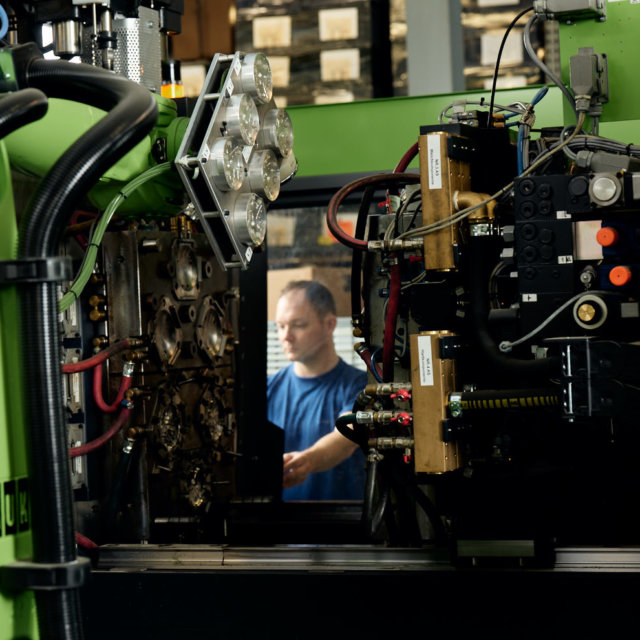

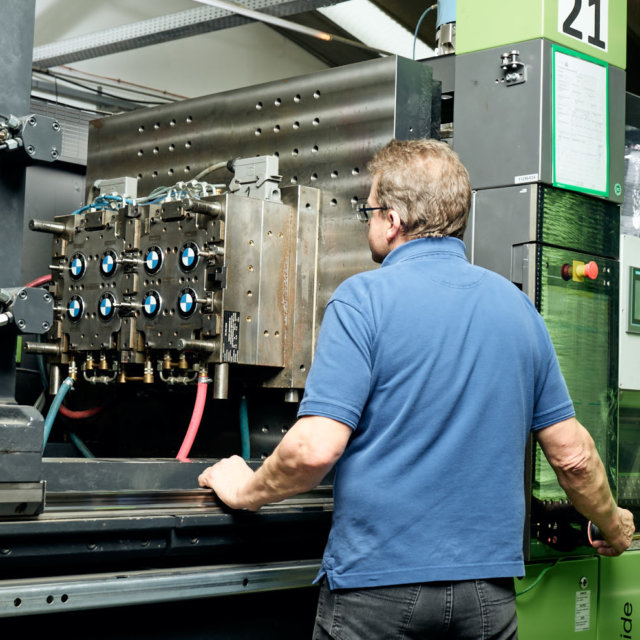

Plastic injection moulding

No matter if 1K or 2K: Plastic injection moulding is one of our core competences. Our machines liquefy thermoplastic plastic pellets and inject them under high pressure into forming moulds. To combine various plastics in one component, we make use of multi-component injection moulding (2K). We have fully-automatic, linked injection moulding assembly platforms of the latest generation made by Engel that feature a clamping force of 30 to 800 tons. ULBRICHTS Automotive processes the following plastics – of course also in combination with additives like glass fibres and minerals, etc.

- ABS (galvanic chrome-plating)

- Polyamides for high strengths

- ASA

- PMMA/acryl (for high-gloss surfaces)

- Polycarbonates (transparent plastics)

- Polypropylene

- PPE (injectable elastomers)

Surface technology

Endless design options: The requirements towards the look and feel of surfaces on and inside automobiles are changing continuously. For decades already, we have been meeting our customers’ high expectations. To do so, we rely on various surface technologies:

- Galvanic chrome-plating

- Screen printing on aluminium

- Painting

- Adhesive vinyl graphics

- Printing

To provide elements with a particularly glossy appearance, they are galvanically chrome-plated. The protective metallic cover that consists of various layers is not only meant to look good. It makes our products resistant to corrosion and ensures the remain an eye-catcher in the long run even if they are exposed to various kinds of exterior impact.

Colours are important distinctive features for our customers. Silk screening allows for applying any desired colour onto the aluminium.

Various one-, two-, or multi-coat processes do not only serve to apply the requested colour and gloss variety to the surface. The varnish applied also protects the base from environmental impact. We paint plastics as well as chrome-plated surfaces. Depend on the series’ volume, this is made fully-automatically or manually.

It doesn’t always have to be paint. Adhesive vinyl graphics offer numerous opportunities for surface enhancement. Coloured adhesive vinyl and decals can create sharp contrasts between different surfaces. For this purpose, they are applied to the component using various techniques. This creates the characteristic design elements of contemporary dream cars.

Pat printing is the perfect technique for printing parts of surfaces. Whether in one or various colours: the pad absorbs the liquid paint and then precisely prints it onto the respective components as requested.

Fully automatic assembly with integrated quality control

What does it take to produce 100,000 different emblems, logos, and design elements per day in top quality? The answer is: fully-automated processes with integrated quality control. All our products consist of multiple components made in sequential work steps and subsequently assembled automatically. Our proprietary manufacturing platforms ensure accurate assembly, quality control and packaging included. Fast, safe and highly efficient.

Metal stamping

Our products form brands: In order to produce them, we also stamp metals – especially aluminium. To meet our customers’ high expectations, each and every angle and radius need to be absolutely accurate. Before they are being produced in series, the prototypes of ULBRICHTS Automotive undergo all stages of development – from conception to the finished component. This enables us to realize individual requests particularly fast.

Back injection moulding of aluminium

A perfect team: its specific material properties perfectly qualify aluminium for shaping and moulding processes. Back-injecting aluminium with a thermoplastic support material is a special technique in this context. The close conjunction between aluminium and plastic ensures particularly corrosion-resistant high-quality surfaces. The tools and processes required are proprietarily developed by ULBRICHTS Automotive.